Datacenter Power Electronics

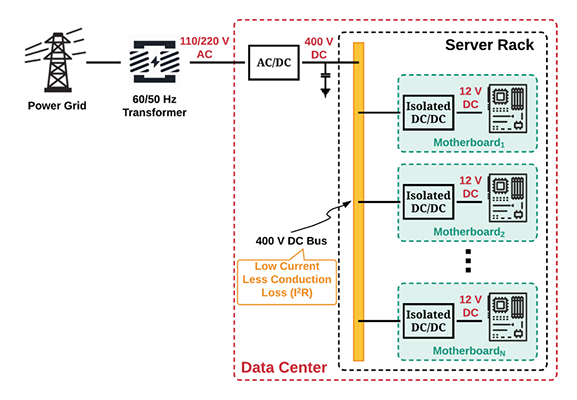

The rapid growth of internet-based devices and cloud computing is promoting the demand for datacenter servers. The traditional power structure of datacenters requires 12 V DC bus-cables to provide power to motherboards on the server racks, and each server rack typically contains about 30 to 35 motherboards. The power usage of a single motherboard is typically between 500 and 1200 W, which means that the current on the 12 V DC bus is considerably high; thus, the conduction loss on the power distribution path is excessive, which reduces the overall system efficiency. To reduce the conduction loss on the power distribution path, a 400 V common DC bus could be utilized among server motherboards. This approach reduces the conduction loss, as the 400 V DC bus carries 33.3 times less current. In this architecture, instead of a large, high-power 400 V to 12 V DC-DC converter, lower-power converters are directly integrated on the server motherboard. The converter is required to step down 360-400 V DC (nominal 380 V DC) to 12 V DC with high efficiency, and its power density should be greater than 12.2 W/cm3 (200 W/in3) to allow the converter to be placed on the motherboard.

The power densities of present high-output-current DC-DC converters with 50-100 kHz frequency are typically less than 3.1 W/cm3 (50 W/in3), which make them impossible to be integrated with server motherboards. This project, therefore, focuses on developing a 750 W onboard DC-DC converter, which can satisfy all the requirements. The major technical challenges addressed by these requirements are achieving a power density over 12.2 W/cm3 and maintaining high efficiencies at different loads.

In this project, GaN-based switches are used as primary-side switches to achieve high operation frequency. A planar transformer is used in this design due to its features such as low profile, high power density and efficient heat dissipation. To further reduce the size of the converter, the resonant inductor is integrated within the planar transformer as leakage inductance. The leakage inductance of the transformer can be adjusted by controlling the distance between primary and secondary windings.

Finally, A 450 kHz, 360-400 VDC input, 12 VDC output, 750 W LLC converter prototype with adjustable-leakage-inductance planar transformer is built and tested. The power density of the system is 15.4 W/cm3 including an auxiliary power supply. The peak efficiency of the overall system is over 95%.